Automation And robotics are two different but closely related concepts. Both are part of the daily life of societies in several industries and help them be profitable stream and optimize internal processes.

Automation concerns a wide concept that includes the use of technology to automatically perform tasks without direct human intervention.

Robotics is a combination of various sciences such as engineering and computer science used to design, build and operate robots. Robots are programmable that can complete autonomously or semi -autonomously.

In this article we emphasize Key differences between automation and robotics. Then we go in more detail about everyone and end with future trends.

Key differences and common features

Automation applies to the task automation process using technology that may or may not include robots.

Examples of automation technologies that are not robotics include computer systems programming, specialized industrial process control software, or building management systems such as automated lighting or HVAC controls.

Robotics focuses on the design, construction and programming of robots to perform specific tasks.

Robots can be automated but may not be. For example, some robots require a person to control them, such as remote control drones.

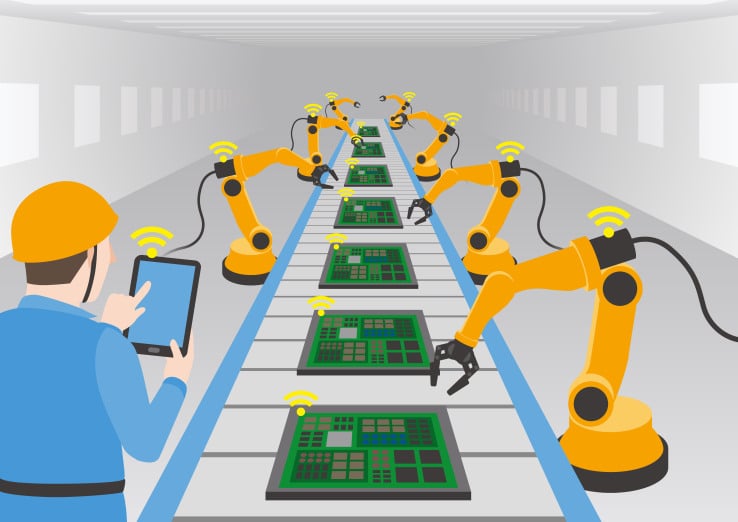

Example of automated robots are everywhere, from those designed to build components on the production line to those that vacuum floors or mowing lawns.

Robotics and Automation technology It can also be used to separate the project and needs of the project or company. As we will see, both fields provide similar benefits Physical processes,, Business processesand the company’s competitiveness.

What is automation?

Automation means using computer software, machines or other technologies to perform a task that a human worker would otherwise perform. This causes the time of this worker to focus on more complicated and strategic activities.

There are many types of automation, from fully mechanical to fully virtual and from very simple to extremely complex.

Types Automation

Let’s take a look at the two main automation types: software automation and industrial automation.

Software automation is used to perform normal tasks performed by people on computers. There are many branches, types and trends of software automation: test automation, robotic process automation (RPA), intelligent automation and more.

Software automation involves automating robotic processes where robots process recurring digital tasks and intelligent process automation that integrate with AI for smarter automation. Automation of office tasks can contribute to improving the business process.

AutomationA physical process that is automated by automated physical robots and special control systems. It may include disposable machines performing specific tasks or a fully automated production line. Industrial automation is an increasingly important aspect of optimization of production and production processes. There are different types of industrial automation:

- Firm automation Also known as strict automation, it includes the implementation of systems designed to perform specific tasks in a repeated way and in one lease. A common example of fixed automation is the mounting line in the automotive industry, where robotic weapons perform mounting tasks.

- Programmable automation It allows agility in production because the software is reprogrammed or reconfigured to adapt to different products or processes. In contrast to fixed automation allows programmable automation and robot be reprogrammed to change the sequence of operations or production parameters as needed.

- Flexible automationIt will take a step further by allowing the production systems to fit rapidly to meet the developing market as an example of a flexible automation would be a factory creating electronic components where production cells adapt to the change of design or product demand.

- Intelligent automationAlso Red this as cognitive automation or industry 4.0, related to advanced technologies such as artificial intelligence, machine learning and data analytics to optimize industrial processes. Intelligent automation allows autonomous decision making and adaptation in real time changes in the production environment. Example of intelligent automation would predict and prevent machine -analysis and prevent machine breakdowns.

Automation Yarn

Automation is about using technology to make tasks easier and more efficient. It includes the use of machines or computer software to perform tasks that people usually do. By delegating tasks usually performed by people automation relates to several common:

- Lack of work: Includes difficult to find, train and maintain workers who perform a repertite condition. Automation of taking these jobs not only helps to reduce the number of workers, but also workers to specialize in more intersing and strategic activities that are likely to encourage them to stay in society in the long run.

- Safety: Recurrent tasks represent health and safety from ASYY exhibitions to insult. Automation can take these security risks.

- Efficiency: Unlike humans, it can run continuously without being left, and the specification remains. This increases the output and reduces the error.

- Competitive edge : Companies that implement automated systems gain a complete advantage by improving efficiency, reducing cost and offering better products.

In the core is automation o Increasing efficiency and accuracy in the digital and physical world.

.

What is robotics?

In most cases, the robotics of the Broade automation is and focuses on physical robots. It includes more disciplines for designing, building, programming and using robotic machines. These robots can transform the way we work.

The aim of robotics is generally to automate tasks or processes.

Types of robots

Let’s take a look at three types of robots: industrial robots, service robots and humanoid robots.

- Industrial robots They are used in factories and warehouses to automate tasks such as welding, assembly and material handling. They are designed for accuracy, speed and repeatability and are often stationary. Industrial robots are universal and can be reprogrammed to perform different tasks. They are most commonly used in print, packaging, welding, machine selection, material handling and metal work.

- Robot service Are used in homes, hospitals, hotels, offices, airports, museums and shopping centers to clean employment, greet visitors, gold production shops. They are forced to interact with people and are more useful and less accessible and less complex than industrial robots. An example includes a robot vacuum cleaner or a lawn mower or an interactive robot in a doctoral office.

- Humanoid robots Look like human beings. They are programmed to interact with the environment that a person can and can have facial features to mimic emotions. Sophia is an example of a humanoid robot. Sophia is built into neural networks and artificial intelligence to recognize human faces and understand their gestures and emotions and respondents.

The benefits of robotics

Robotics have countless benefits, but not only:

- Improved Ackeracy and Consistency – Robotic systems are precisely, so their output is accurate and consists. They practically eliminate a human mistake.

- Improved product quality – Robots are not influenced by fatigue or distraction due to repeated tasks as they are. This improves quality insurance.

- More efficiency and production – Unlike human workers, robots do not have to take breaks or set up work shifts, so production can work 24/7. Quality insurance means less unnecessary products and more yield.

- Creating jobs and maintaining employees – Acceptive shelter, robots do not rule out jobs, but create new ones! Now that manual and repeated tasks can be delegated to the machine, one can get up in roles where skills can use and develop skills. For example, multiple software and programmers developers are needed to service and maintain robots and will have to require new professionals that the automated production line runs smoothly. This career procedure often leads to the inclusion of used satisfaction and maintaining.

- Increased workplace safety – Work on the production line can be particularly dangerous for human workers. Allowing robots accept strenuous, recurring tasks will lead people out of the way of damage.

Future trends in automation and robotics

So what does the future have for automation and robotics?

Since both areas continue to revolutionize industries by bringing the accuracy, efficiency and safety of various processes, automation and robotics transform the existing industries and also act as a catalyst for the new sectors that appear.

Here are our predictions for upcoming trends in automation and robotics:

- Integration AI – Constant progress in AI and machine learning increases more intelligent and adaptive automation systems. This means that future robots exceed repeating performance tasks; They will also be able to take complex decisions, analyze real -time data and learn from their Surown, increase productivity and minimize human error.

- Collaborative robots (Cobots) – Collaborative robots, also NOWN as Cobots, are designed to work with human employees without security barriers. They are designed with regard to safety and flexibility, allowing them to perform various simple or complex tasks while staying straight enough to program and handle. We will see integration into their implementation across industries.

- Expansion in non -industrial sectors– The versatility of robotics and automation allows their application in various sectors, including healthcare, agriculture, services and more. Extensive acceptance will lead to uniform growth and innovation, which will contribute to economic stability and creating jobs in new areas outside repeated tasks.

Do you have questions about differences between automation types? Ask us in the comments below or join the discussion on LinkedIn or Facebook.